Carbon Fiber Panel Sheet Fireproof Composite

Please click the button below to contact us.

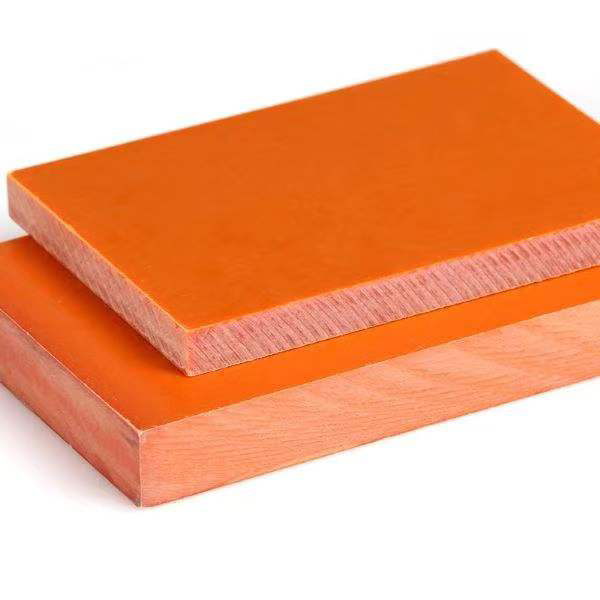

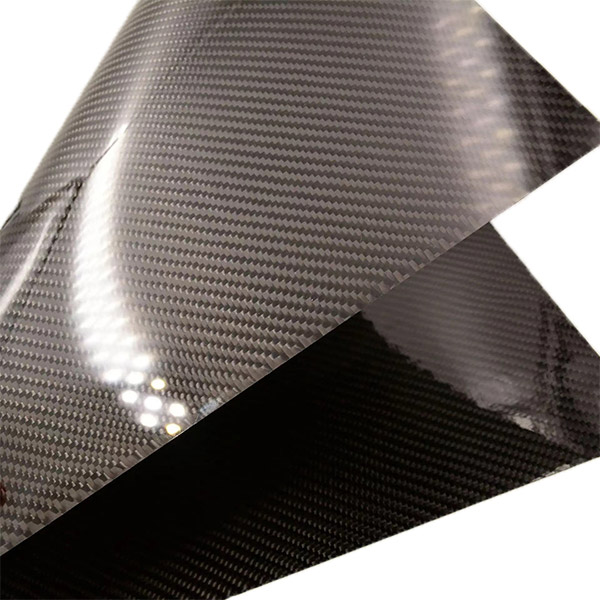

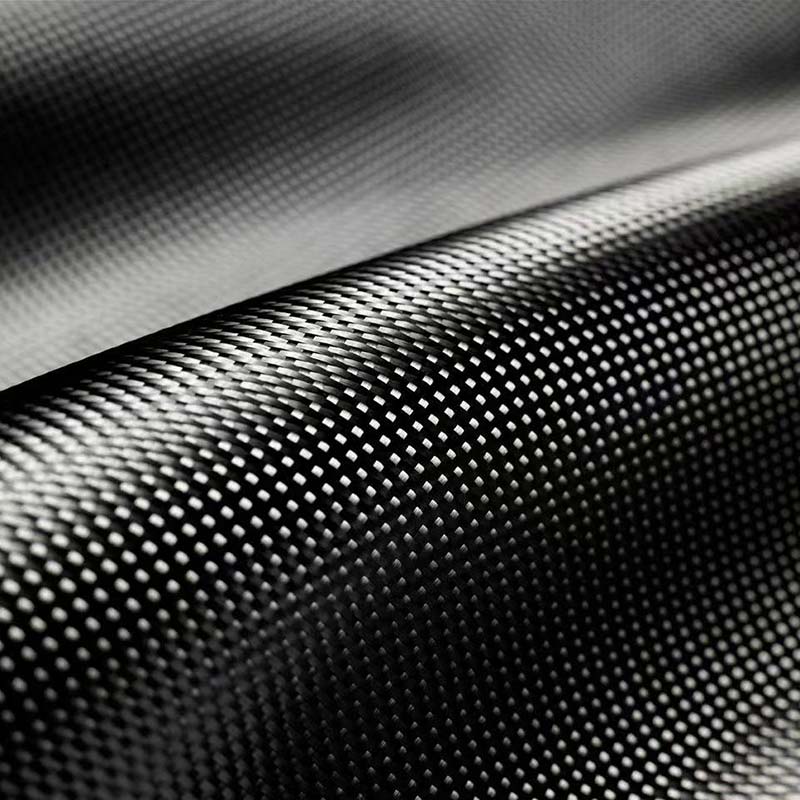

Introduction:A carbon fiber panel sheet is a lightweight and durable material crafted from carbon fibers that are tightly woven together and bonded with a resin. Carbon fiber materials are so strong that even materials made by lower grade carbon fibers.

Product Description

Features:

- Excellent fire resistance: One of the most significant advantages of fire-resistant composite materials is their outstanding fire resistance. They can resist ignition in the event of a fire, providing a safer outdoor environment.

- High safety standards: Meet strict safety standards and regulations established by building codes and fire departments, and provide superior fire hazard protection.

- Durability and longevity: Fire resistant composite materials can withstand various elements including moisture, ultraviolet radiation, and temperature fluctuations, maintaining their structural integrity and aesthetics. Compared to traditional wood floors that are prone to decay, deformation, and insect damage, they provide superior performance and require minimal maintenance.

- Moisture resistance and decay resistance: The combination of wood fibers and plastic polymers creates a barrier that prevents moisture infiltration, reducing the risk of mold, mildew, and decay, making it an ideal choice for outdoor environments.

- Green and environmentally friendly: Made from recycled materials, it reduces the demand for raw materials and minimizes waste, contributing to sustainable building practices and environmental protection efforts.

- Aesthetic Design: Provides a variety of colors, textures, and finishes to choose from, allowing customization of outdoor spaces based on personal style preferences and design aesthetics, enhancing the overall beauty and appeal of outdoor living areas.

- Low maintenance requirements: Unlike traditional wooden flooring, fire-resistant composite materials require minimal maintenance. Typically, regular cleaning with soap and water is sufficient to maintain optimal condition..

- Free of harmful substances: All products use unique formulas and do not contain harmful substances such as asbestos, formaldehyde, benzene, etc. There is no irritating odor, and it is safe and environmentally friendly

Application:

carbon fiber panel sheet FAQs:

What are the primary benefits of carbon fiber panel sheets compared to other materials?

carbon fiber panel sheets offer exceptional strength-to-weight ratio, corrosion resistance, durability, and high stiffness, making them ideal for applications requiring lightweight yet robust material solutions.

Can you customize carbon fiber panel sheets according to our specific requirements?

Yes, we offer customization services to tailor carbon fiber panel sheets to your exact specifications, including dimensions, surface finishes, and resin systems, ensuring optimal performance for your application.

How do you ensure the consistency of carbon fiber panel sheet production?

We implement rigorous quality control measures throughout the manufacturing process, including raw material inspection, precise machining, and thorough testing, to maintain the highest standards of consistency and reliability in our products.

What industries commonly use carbon fiber panel sheets?

Our carbon fiber panel sheets are utilized across various industries, including aerospace, automotive, marine, defense, sports and recreation, industrial equipment, and architectural applications, due to their exceptional performance and versatility.

Can you provide technical assistance and support during the design and implementation phases?

Yes, our team of experienced engineers and technical experts is available to offer comprehensive support and guidance at every stage of your project, from initial design consultation to post-installation assistance, ensuring optimal results and customer satisfaction.

How do carbon fiber panel sheets perform in extreme temperature environments?

Carbon fiber panel sheets exhibit excellent thermal stability and resistance to temperature extremes, maintaining their structural integrity and mechanical properties over a wide range of operating temperatures, from sub-zero to high heat conditions.

What are the recommended methods for cutting and machining carbon fiber panel sheets?

We recommend using specialized cutting tools and machining techniques designed for composite materials to achieve clean and precise cuts without compromising the integrity of the carbon fiber panel sheets. Our technical team can provide guidance on the most suitable methods for your specific application.

Are there any special handling or storage requirements for carbon fiber panel sheets?

Carbon fiber panel sheets should be stored in a clean, dry environment away from direct sunlight and moisture to prevent any degradation or damage to the material. Additionally, proper handling procedures should be followed to avoid excessive bending or impact during transportation and installation.