Chinese Manufacturer Efficient Fireproof Fireproof Composite

Please click the button below to contact us.

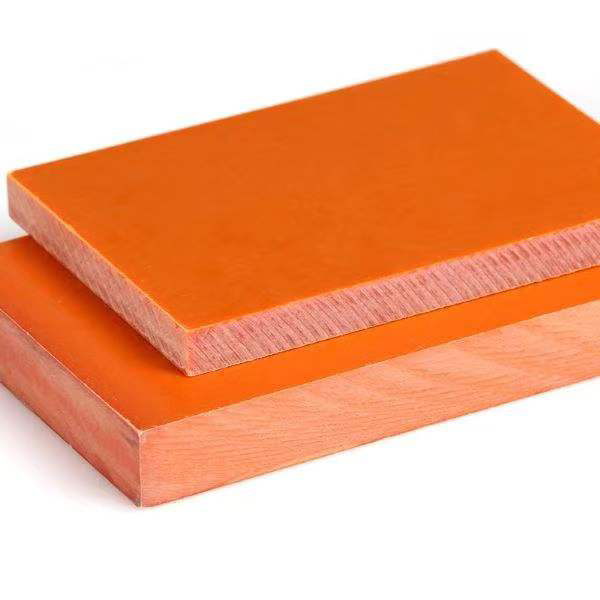

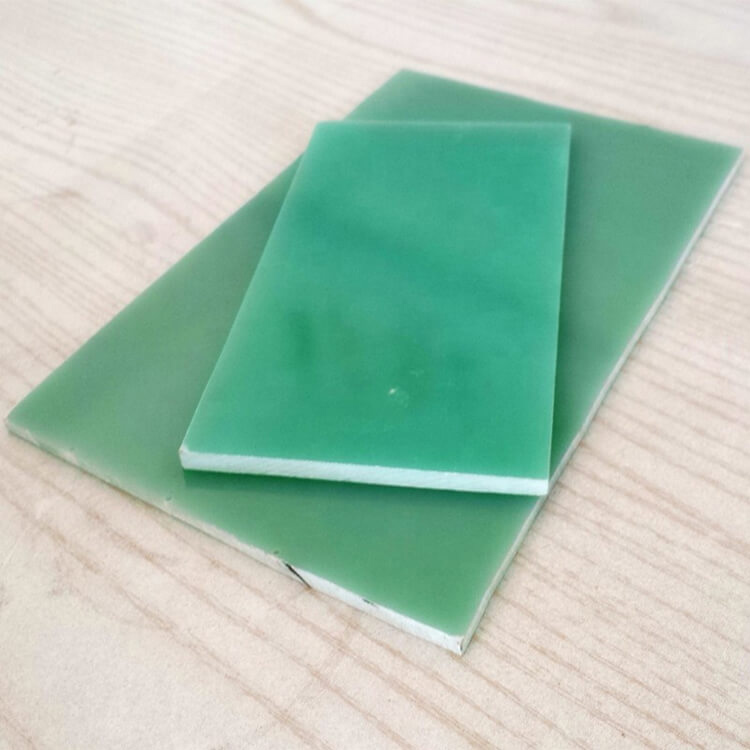

Introduction:Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4 is one of the composite materials that are widely used in electronics. Its components consist of glass fiber cloth soaked in resin called epoxy, and after this it gets hardened through heat or pressure to become a stiff and resilient sheet.

Product Description

Fireproof composite substances refer to substances specially designed to withstand and stand up to excessive temperatures and flames. These substances are generally used in quite a number industries the place fireplace security is crucial, such as construction, aerospace, and car manufacturing.

Parameters:

| Indicator Name | Unit | Indicator Value | |

| Density | g/cm³ | 1.8–2.0 | |

| Water absorption | % | ≤ 0.5 | |

| Vertical layer bending strength | MPa | ≥ 340 | |

| Vertical layer compression strength | MPa | ≥ 350 | |

| Parallel layer impact strength (simple beam method notch) | K J/m² | ≥ 37 | |

| Parallel layer shear strength | MPa | ≥ 34 | |

| Tensile strength | MPa | ≥ 300 | |

| Vertical layer direction electric strength (90 ℃± 2 ℃ in oil) | 1mm | KV/mm | ≥ 14.2 |

| 2mm | ≥ 11.8 | ||

| 3mm | ≥ 10.2 | ||

| Parallel layer direction breakdown voltage (90 ℃± 2 ℃ in oil) | KV | ≥ 40 | |

| Dielectric loss factor (50 Hz) | – | ≤ 0.04 | |

| Insulation resistance | Normality | Ω | ≥ 5.0 × 1012 |

| After immersed in water for 24h | ≥ 5.0 × 1010 | ||

| Flammability (UL-94) | Rating | V-0 | |

Features:

- Efficient furnace prevention: Super insulating fireproof substances have a nano porous shape and ultra-low thermal conductivity, which can obtain excessive hearth resistance tiers with a very small thickness.

- Heat stability: Composite factors have higher warmness balance than single elements at furnace temperatures.

- Infrared shading agent: a key thing that considerably reduces the high-temperature thermal conductivity of materials. The life like determination of infrared shading agent is based totally on the willpower of infrared extinction coefficient and numerical calculations primarily based on Mie scattering theory.

- Fireproof overall performance and elevated protection standards: Fireproof composite ground is relatively valued for its terrific fireproof overall performance and elevated security standards.

- Durability: Fireproof composite floor has excessive sturdiness and can be used for a lengthy time in outside environments.

- Environmental friendliness: With the pursuit of environmental safety and sustainability, fire-resistant composite substances are an increasing number of being used in a range of out of doors area designs.

- Low preservation requirements: Fire resistant composite ground gives a vary of benefits, which includes low protection requirements.

- Lightweight structure: Composite substances are usually composed of strengthened carbon or glass fibers in an natural resin matrix, used to produce light-weight structures.

- Fire protection: The improvement of new substances affords hearth safety with minimal weight loss.

- Thermal overall performance optimization: Six new polymer composite materials, which include furan resin polymerized with cork, have been optimized through analyzing the overall performance of composite substances below excessive temperature conditions.

- Multi layer metallic lamination and mixing technology: gaining knowledge of new composite cloth formulations, such as multi-layer metallic lamination and blending technology, mixing entails forming fiber-reinforced mats from a combination of glass and polymer fibers.

- Thermal radiation effect: due to the melting traits of temperature response, shrewd composite aerogel can exhibit apparent photothermal conversion effect, and has an tremendous radiation cooling effect.

- Fire overall performance verification: Analyze the conduct of structural factors in fire, together with warmness transfer, deflection, and thermal load bearing capacity, via fireplace trying out and FIRE-REIST fabric overall performance verification.

Application:

- Urban underground space: Super insulated fireproof substances will play an vital position in passive fireplace prevention structures in city underground spaces.

- Outdoor area design: inclusive of household courtyards, public entertainment areas, business pedestrian streets, resorts, etc.

- Aerospace: The aerospace subject used for producing light-weight structures.

- Railway and Shipping: The venture consortium consists of ride from the aerospace, railway, and delivery industries.

- Building structure: used to enhance the hearth resistance of constructing structures, decrease gasoline consumption and carbon dioxide emissions.

- Environmental Protection and Sustainability: With the pursuit of environmental safety and sustainability, fire-resistant composite substances are increasingly more being utilized in a number out of doors house designs.

- Fireproof Deck: With the growing demand for fireproof decks, modern advances in composite substances and manufacturing tactics will similarly beautify the overall performance and beauty of fireproof composite flooring.

FAQ:

What is Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4 is a type of composite material composed of woven fiberglass cloth impregnated with an epoxy resin binder. It is known for its excellent electrical insulation properties and mechanical strength.

What are the key features of Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4 offers high mechanical strength, good electrical insulation properties, flame resistance, and excellent dimensional stability.

What industries commonly use Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s find extensive use in industries such as electronics, telecommunications, automotive, aerospace, and electrical equipment manufacturing due to their superior insulation and mechanical properties.

Can Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s be customized according to specific requirements?

Yes, we offer customization services for Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s to meet the specific size, thickness, and surface finish requirements of our customers.

Are Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s compliant with industry standards and regulations?

Yes, our Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s adhere to industry standards and regulations such as [specify relevant standards or certifications], ensuring quality and reliability.

What are the advantages of using Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s over other materials?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s offer advantages such as high strength-to-weight ratio, excellent electrical insulation, flame resistance, and dimensional stability, making them ideal for various demanding applications.

Can Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s be machined or fabricated easily?

Yes, Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s can be easily machined, drilled, milled, and fabricated using standard woodworking tools or CNC machinery, allowing for precise customization.

Do Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s require any special handling or storage conditions?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s should be stored in a dry and cool environment away from direct sunlight and moisture to maintain their properties. Proper handling techniques should be followed to prevent damage.

What is the recommended method for bonding or joining Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s can be bonded using epoxy adhesives specifically formulated for bonding fiberglass materials. Surface preparation and proper adhesive selection are crucial for achieving strong and durable bonds.