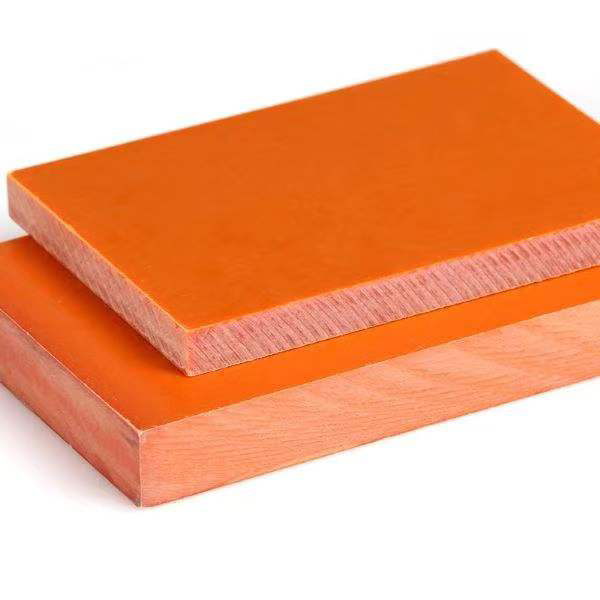

Custom Carbon Fiber Laminated Panels

Please click the button below to contact us.

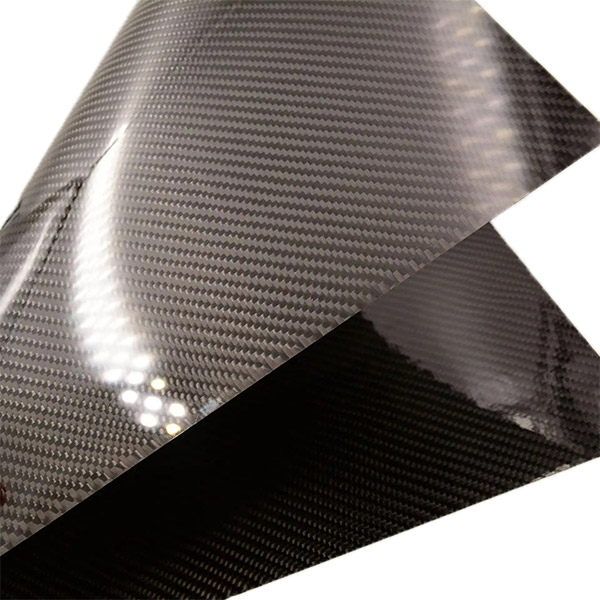

Introduction:A Custom Carbon Fiber Laminated Panels is a lightweight and durable material crafted from carbon fibers that are tightly woven together and bonded with a resin. Carbon fiber materials are so strong that even materials made by lower grade carbon fibers.

Product Description

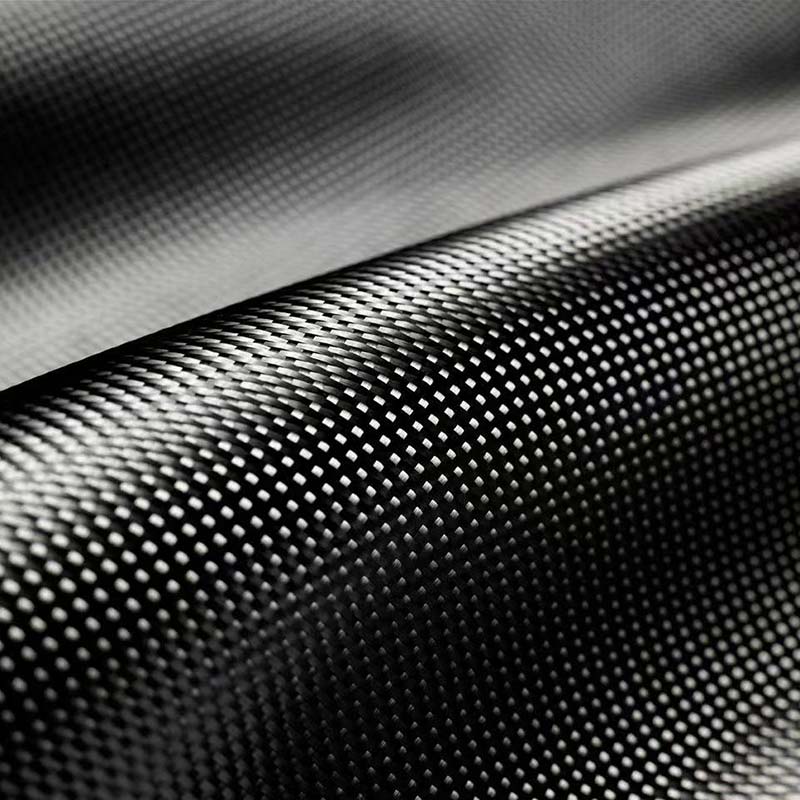

A Custom Carbon Fiber Laminated Panels is a lightweight and durable material crafted from carbon fibers that are tightly woven together and bonded with a resin. carbon fiber materials are so strong that even materials made by lower grade carbon fibers, e.g. T300, have great strength if designed and manufactured in a proper way. Carbon fiber parts are light weighted, compared with similar components made by metal. Carbon fiber composite materials are used to make high-performance sports equipment, including bicycle frames, fishing rods, automobile body parts, frames for models, and more. High-quality carbon fiber materials are applied in aviation industries to replace traditional alloys.

Custom Carbon Fiber Laminated Panels Features:

1. Custom Carbon Fiber Laminated Panels are highly recognized for their strength-to-weight ratio that is exceptional making them very strong while still being light. This is a valuable feature in industries like aerospace and automotive where reduction of weight is crucial.

2. Stiffness: Carbon fiber composites show high levels of stiffness hence excellent resistance against mechanical loads, which lead to deformation. That stiffness contributes to the performance and structural integrity of composite carbon fibre components overall.

3. Corrosion Resistance: Carbon fibre materials were by nature corrosion resistant and hence they can be used in environments which are harsh such as those that might cause metals to degrade over time.

4. Low Thermal Expansion: High temperature resistance and low thermal conductivity are typical attributes of carbon fiber composites with low coefficients of thermal expansion, meaning they expand or contract minimally with changes in temperature. By doing so, this attribute increases dimensional stability and reduces the risk for warping or distortion under variable thermal conditions.

5. Electrical Conductivity: The inherent electrical conductivity of carbon fibers can be advantageous in applications requiring electrical grounding or dissipation of electrostatic charges.

6. Customizability: Weave patterns, resin systems, and fiber orientations are some ways that carbon fiber materials could be customized too high extents. This versatility allows engineers to tailor the mechanical properties of carbon fibre components to specific performance requirements.

Custom Carbon Fiber Laminated Panels Application:

The following are some of the general applications of carbon fiber panel sheets in various industries:

1. Aerospace: In making aircraft structures like wings, fuselages and interior components, carbon fiber panel sheets have a wide use in the aerospace industry due to their high strength-to-weight ratio, helping to decrease overall aircraft weight thus enhancing fuel efficiency and performance.

2. Automotive: Custom Carbon Fiber Laminated Panels are used in manufacturing lightweight body panels, chasis components and interior trims within the automotive sector as well. They keep their usage within high-performance vehicles that increase speed, handling and fuel economy while maintaining the vehicle’s structural integrity and safety.

3. Marine: Hulls, decks, and other structural components of marine vessels such as boats and yachts are made from carbon fiber panel sheets. They are resistant to corrosion as well as water absorption coupled with a high strength property that makes them suitable for marine environments.

4. Sports and Recreation: In sports equipment such as bicycles, tennis rackets, golf clubs or helmets among others; carbon fiber panel sheets can be found all over the place. They help reduce weights while stiffening them up for enhanced performance and maneuverability across various forms of sport activities.

5. Industrial: The industries employ these sheets in different industrial uses like manufacturing equipment, machine parts or structural reinforcements amongst many others where aspects including high stiffnesses can be realized along with fatigue resistance & dimensional stability which lead to better performances and longer lifetimes under industrial conditions.

6. Renewable Energy: Wind turbine blades and solar panel frames are two main areas where carbon fiber composite panels feature prominently with a view to developing renewable energy systems.Because they posses strong mechanical properties but yet light enough to facilitate efficient energy production even under harsh weather environments.

7.Medical: These materials have also been used in medical field especially for making positioning devices for patients surgical tables imaging devices etc.Radiolucent properties allow clear imaging during medical procedures.

8. Civil engineering and construction: Carbon fiber composite panels are increasingly being used in civil engineering and construction.An example is where they reinforce structures such as bridges, buildings etc.They have high strength-to-weight ratio and corrosion resistance making them a lightweight and long-lasting solution for constructions.

9. Consumer electronics: They are also aesthetically appealing with high strength properties which make them suitable to be incorporated into electronic devices such as laptops, smartphones, audio equipment among other consumer electronic gadgets.

10. Defense/Security: Military vehicles, armor plating and protective gear are some of the things manufactured from carbon fiber panel sheets in defense and security sectors thanks to their ballistic protection properties and light weight nature.

Custom Carbon Fiber Laminated Panels FAQs:

What are the primary benefits of Custom Carbon Fiber Laminated Panels compared to other materials?

Carbon fiber panel sheets offer exceptional strength-to-weight ratio, corrosion resistance, durability, and high stiffness, making them ideal for applications requiring lightweight yet robust material solutions.

Can you customize carbon fiber panel sheets according to our specific requirements?

Yes, we offer customization services to tailor carbon fiber panel sheets to your exact specifications, including dimensions, surface finishes, and resin systems, ensuring optimal performance for your application.

How do you ensure the consistency of Custom Carbon Fiber Laminated Panels production?

We implement rigorous quality control measures throughout the manufacturing process, including raw material inspection, precise machining, and thorough testing, to maintain the highest standards of consistency and reliability in our products.

What industries commonly use Custom Carbon Fiber Laminated Panels?

Our Custom Carbon Fiber Laminated Panels are utilized across various industries, including aerospace, automotive, marine, defense, sports and recreation, industrial equipment, and architectural applications, due to their exceptional performance and versatility.

Can you provide technical assistance and support during the design and implementation phases?

Yes, our team of experienced engineers and technical experts is available to offer comprehensive support and guidance at every stage of your project, from initial design consultation to post-installation assistance, ensuring optimal results and customer satisfaction.

How do Custom Carbon Fiber Laminated Panels perform in extreme temperature environments?

Custom Carbon Fiber Laminated Panels exhibit excellent thermal stability and resistance to temperature extremes, maintaining their structural integrity and mechanical properties over a wide range of operating temperatures, from sub-zero to high heat conditions.

What are the recommended methods for cutting and machining Custom Carbon Fiber Laminated Panels?

We recommend using specialized cutting tools and machining techniques designed for composite materials to achieve clean and precise cuts without compromising the integrity of the carbon fiber panel sheets. Our technical team can provide guidance on the most suitable methods for your specific application.

Are there any special handling or storage requirements for Custom Carbon Fiber Laminated Panels?

Custom Carbon Fiber Laminated Panels should be stored in a clean, dry environment away from direct sunlight and moisture to prevent any degradation or damage to the material. Additionally, proper handling procedures should be followed to avoid excessive bending or impact during transportation and installation.