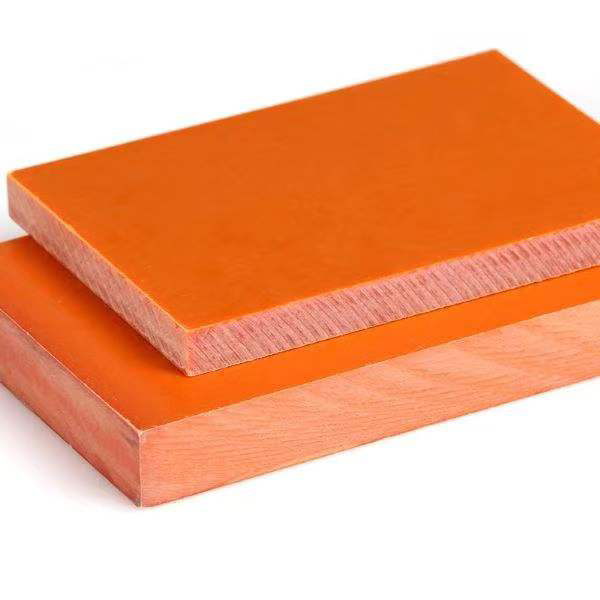

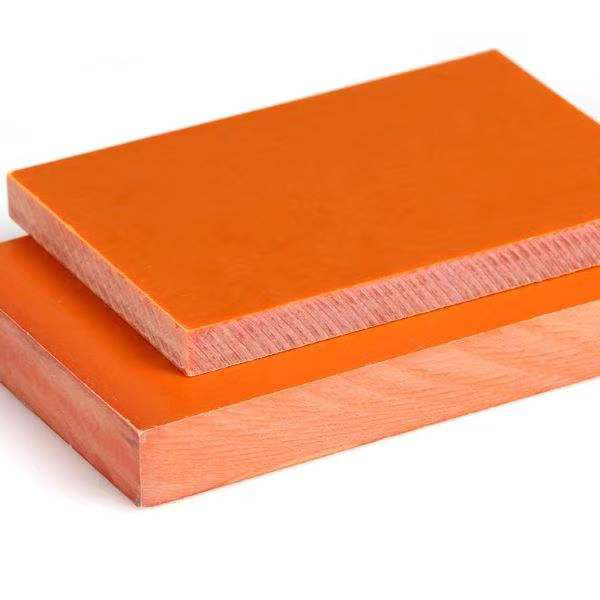

Fiberglass FR4 Insulation Material

Please click the button below to contact us.

Introduction:FR4 fiberglass sheet is one of the composite materials that are widely used in electronics. Its components consist of glass fiber cloth soaked in resin called epoxy, and after this it gets hardened through heat or pressure to become a stiff and resilient sheet.

Product Description

Fiberglass FR4 Insulation Material is one of the composite materials that are widely used in electronics. Its components consist of glass fiber cloth soaked in resin called epoxy, and after this it gets hardened through heat or pressure to become a stiff and resilient sheet. The reason why these sheets are commonly used as printed circuit board (PCB) substrates is their ability to hold complex circuitry as well as operate under severe conditions. FR4 sheets also tend to retard flame hence they can be used in areas where fire hazard may arise. They have outstanding electrical insulating abilities, excellent mechanical strength, and can tolerate high temperatures plus resistance to chemicals.

Fiberglass FR4 Insulation Material Parameters:

| Indicator Name | Unit | Indicator Value | |

| Density | g/cm³ | 1.8–2.0 | |

| Water absorption | % | ≤ 0.5 | |

| Vertical layer bending strength | MPa | ≥ 340 | |

| Vertical layer compression strength | MPa | ≥ 350 | |

| Parallel layer impact strength (simple beam method notch) | K J/m² | ≥ 37 | |

| Parallel layer shear strength | MPa | ≥ 34 | |

| Tensile strength | MPa | ≥ 300 | |

| Vertical layer direction electric strength (90 ℃± 2 ℃ in oil) | 1mm | KV/mm | ≥ 14.2 |

| 2mm | ≥ 11.8 | ||

| 3mm | ≥ 10.2 | ||

| Parallel layer direction breakdown voltage (90 ℃± 2 ℃ in oil) | KV | ≥ 40 | |

| Dielectric loss factor (50 Hz) | – | ≤ 0.04 | |

| Insulation resistance | Normality | Ω | ≥ 5.0 × 1012 |

| After immersed in water for 24h | ≥ 5.0 × 1010 | ||

| Flammability (UL-94) | Rating | V-0 | |

Fiberglass FR4 Insulation Material Features:

1. Material Composition: Also known as flame retardant, FR-4 epoxy sheet is a composite material made from epoxy resins and woven fiberglass cloth.

2. Mechanical Strength: Its fiberglass contents give it a high degree of mechanical strength hence its suitability in many structural applications.

3. Electrical Insulation: Perfect electrical insulating properties make the materials suitable for printed circuit board (PCB) and other electrical insulation uses.

4. Thermal Stability: This indicates good thermal stability, meaning that it retains its properties over a broad temperature range; normally, it can bear heat up to around 130 to 140 degrees C.

5. Flame Retardancy: Consequently, flame resistant according to UL94-V0 standard for electronic safety measures.

6. Dimensional Stability: Because of its high dimensional stability i.e., under mechanical stress or thermal cycling it does not deform easily under such conditions.

7. Moisture Resistance: It absorbs very little water thus maintaining electric insulating properties even when placed in humid surroundings.

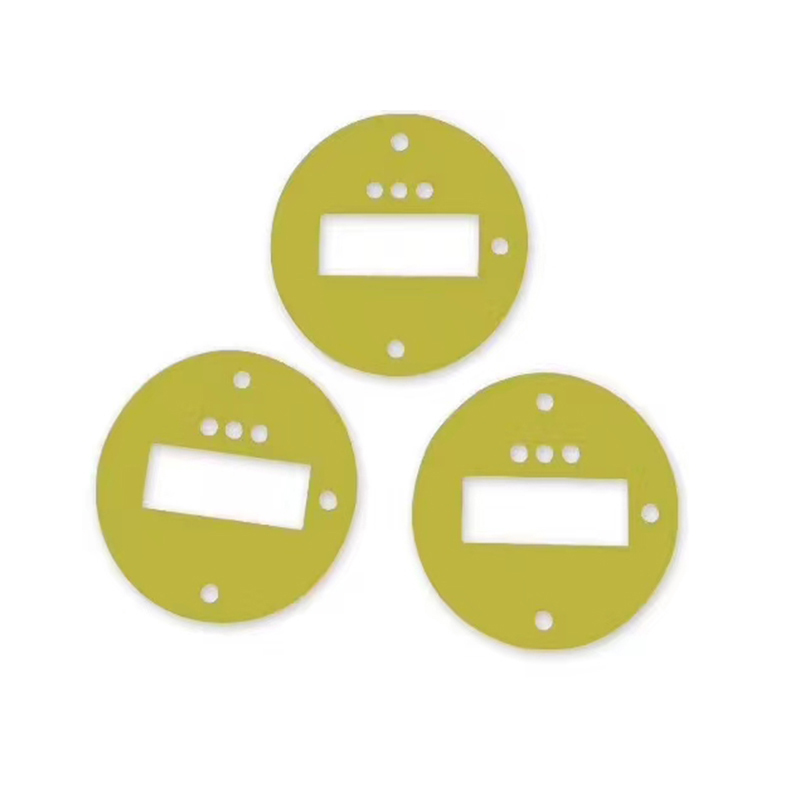

8. Machinability: Further tolerance of it against drilling cutting and shaping by means of conventional tools without major wear also add up to this material’s machinability characteristics.

9. Chemical Resistance: The main benefit of this feature is that it helps maintain the integrity of the material in harsh environments as well as chemical resistance towards a wide range of chemicals and solvents.

Fiberglass FR4 Insulation Material Application:

It is widely used as structural parts in motors and electrical equipment, including various switches, electrical insulation, FPC reinforcement boards, carbon film printed circuit boards, computer drilling pads, mold fixtures, etc. (PCB testing Frame); and can be used in humid environments and transformer oil.

Fiberglass FR4 Insulation Material FAQs:

What is Fiberglass FR4 Insulation Material?

FR4 Fiberglass Sheet is a type of composite material composed of woven fiberglass cloth impregnated with an epoxy resin binder. It is known for its excellent electrical insulation properties and mechanical strength.

What are the key features of Fiberglass FR4 Insulation Material?

FR4 Fiberglass Sheet offers high mechanical strength, good electrical insulation properties, flame resistance, and excellent dimensional stability.

What industries commonly use Fiberglass FR4 Insulation Material?

FR4 Fiberglass Sheets find extensive use in industries such as electronics, telecommunications, automotive, aerospace, and electrical equipment manufacturing due to their superior insulation and mechanical properties.

Can Fiberglass FR4 Insulation Material be customized according to specific requirements?

Yes, we offer customization services for FR4 Fiberglass Sheets to meet the specific size, thickness, and surface finish requirements of our customers.

AreFiberglass FR4 Insulation Material compliant with industry standards and regulations?

Yes, our FR4 Fiberglass Sheets adhere to industry standards and regulations such as [specify relevant standards or certifications], ensuring quality and reliability.

What are the advantages of using Fiberglass FR4 Insulation Material over other materials?

FR4 Fiberglass Sheets offer advantages such as high strength-to-weight ratio, excellent electrical insulation, flame resistance, and dimensional stability, making them ideal for various demanding applications.

Can Fiberglass FR4 Insulation Material be machined or fabricated easily?

Yes, FR4 Fiberglass Sheets can be easily machined, drilled, milled, and fabricated using standard woodworking tools or CNC machinery, allowing for precise customization.

Do Fiberglass FR4 Insulation Material require any special handling or storage conditions?

FR4 Fiberglass Sheets should be stored in a dry and cool environment away from direct sunlight and moisture to maintain their properties. Proper handling techniques should be followed to prevent damage.

What is the recommended method for bonding or joining Fiberglass FR4 Insulation Material?

FR4 Fiberglass Sheets can be bonded using epoxy adhesives specifically formulated for bonding fiberglass materials. Surface preparation and proper adhesive selection are crucial for achieving strong and durable bonds.