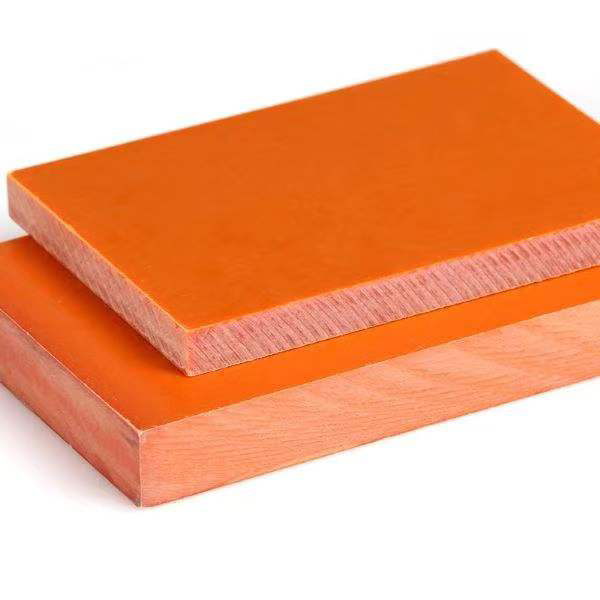

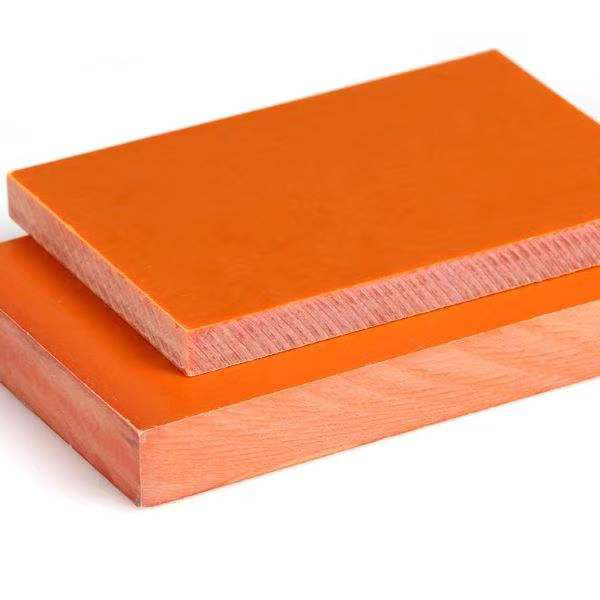

FR2 Phenolic Resin Laminate Sheet

Please click the button below to contact us.

Introduction:This Phenolic Resin Laminate Sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. It has high mechanical properties, dielectric properties and flame retardant properties, good heat resistance and moisture resistance, and good machinability. Composite materials are widely used in electronics and FR-4 Glass Epoxy Sheet is a typical example of that. It is made up of a woven fiberglass cloth, which has been soaked with epoxy resin and then hardened at high temperature and pressure to form a tough rigid sheet. These sheets have excellent electrical insulation properties, high mechanical strength and are capable of resisting heat damage as well as reaction with many chemicals. They are the most commonly used substrate materials for printed circuit boards (PCBs) because they can support complex circuitry configurations while surviving hostile operating environments . FR-4 sheets are also fire-retardant hence this attribute makes them an ideal choice for applications demanding fire safety precautions.

Product Description

This Phenolic Resin Laminate Sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. It has high mechanical properties, dielectric properties and flame retardant properties, good heat resistance and moisture resistance, and good machinability. Composite materials are widely used in electronics and FR-4 Glass Epoxy Sheet is a typical example of that. It is made up of a woven fiberglass cloth, which has been soaked with epoxy resin and then hardened at high temperature and pressure to form a tough rigid sheet. These sheets have excellent electrical insulation properties, high mechanical strength and are capable of resisting heat damage as well as reaction with many chemicals. They are the most commonly used substrate materials for printed circuit boards (PCBs) because they can support complex circuitry configurations while surviving hostile operating environments . FR-4 sheets are also fire-retardant hence this attribute makes them an ideal choice for applications demanding fire safety precautions.

Phenolic Resin Laminate Sheet Parameters:

| Indicator Name | Unit | Indicator Value | |

| Density | g/cm³ | 1.8–2.0 | |

| Water absorption | % | ≤ 0.5 | |

| Vertical layer bending strength | MPa | ≥ 340 | |

| Vertical layer compression strength | MPa | ≥ 350 | |

| Parallel layer impact strength (simple beam method notch) | K J/m² | ≥ 37 | |

| Parallel layer shear strength | MPa | ≥ 34 | |

| Tensile strength | MPa | ≥ 300 | |

| Vertical layer direction electric strength (90 ℃± 2 ℃ in oil) | 1mm | KV/mm | ≥ 14.2 |

| 2mm | ≥ 11.8 | ||

| 3mm | ≥ 10.2 | ||

| Parallel layer direction breakdown voltage (90 ℃± 2 ℃ in oil) | KV | ≥ 40 | |

| Dielectric loss factor (50 Hz) | – | ≤ 0.04 | |

| Insulation resistance | Normality | Ω | ≥ 5.0 × 1012 |

| After immersed in water for 24h | ≥ 5.0 × 1010 | ||

| Flammability (UL-94) | Rating | V-0 | |

Phenolic Resin Laminate Sheet Features:

FR2 Epoxy Fiberglass Laminate Sheet, also known as flame retardant No. 2 epoxy fiberglass laminate, is a high-performance composite material. The following is a point-by-point introduction in English about its characteristics:

1. Fire Resistance:

The "FR" marking in FR2 means "Fire Resistant", which means that it is strictly made to contain fire spread and smoke development during fire accidents. The material meets or exceeds various fire-rating standards, which makes it suitable for areas where there are concerns about fire safety.

2. Electrical Properties:

Highly insulating with a high dielectric strength and low electric conductivity, FR2 epoxy fiberglass laminate sheet has perfect electric properties. It is widely used in electrical and electronic applications requiring insulation and electrical isolation.

3. Mechanical Strength:

Tensile strength, flexural strength, and impact resistance are among the mechanical strengths that come with the glass reinforced elements of FR2 laminate sheet. Dimensional changes of this material under moderate to high temperature variations are minimal hence its application at extensive operating ranges.

4. Dimensional Stability:

FR2 Laminate Sheet is dimensionally stable hence does not move or change shape in response to environmental conditions such as moisture or temperature fluctuations. When consistent dimensions matter such as precision application FR2 laminates excellently serve that purpose.

5. Ease of Processing:

It is also possible to bond or laminate using adhesives with other materials allowing for greater flexibility in design and production methods and can be machined just like normal metals by cutting drilling routing milling etc with common commercial tools e.g. routers, hacksaws drills etc.

Phenolic Resin Laminate Sheet Application:

It is widely used as structural parts in motors and electrical equipment, including various switches, electrical insulation, FPC reinforcement boards, carbon film printed circuit boards, computer drilling pads, mold fixtures, etc. (PCB testing Frame); and can be used in humid environments and transformer oil.

Phenolic Resin Laminate Sheet FAQs:

What are Phenolic Resin Laminate Sheets made of?

Phenolic Resin Laminate Sheets are made from layers of paper or fabric impregnated with phenolic resin and compressed under high heat and pressure to create a durable, solid material.

What applications are suitable for Phenolic Resin Laminate Sheets?

These sheets are ideal for electrical insulation, mechanical components, and decorative applications due to their excellent mechanical strength and electrical insulation properties.

How durable are Phenolic Resin Laminate Sheets?

They are extremely durable, offering high resistance to moisture, chemicals, and heat, making them suitable for demanding environments.

Are Phenolic Resin Laminate Sheets environmentally friendly?

Yes, they are environmentally friendly as they do not emit harmful substances during their lifecycle and can be disposed of safely.

What are the standard sizes and thicknesses available?

We offer a variety of standard sizes and thicknesses, but custom sizes can also be manufactured to meet specific requirements.

How do Phenolic Resin Laminate Sheets perform under high temperatures?

These sheets can withstand high temperatures without degrading, making them ideal for applications involving extreme heat.

What is the electrical insulation property of these sheets?

Phenolic Resin Laminate Sheets provide excellent electrical insulation, which makes them suitable for use in electrical and electronic applications.

Can these sheets be machined or fabricated?

Yes, Phenolic Resin Laminate Sheets can be easily machined, drilled, and fabricated to suit various industrial applications.

How does the material perform in terms of chemical resistance?

Phenolic Resin Laminate Sheets exhibit high resistance to a wide range of chemicals, making them suitable for chemical processing environments.

Are these sheets flame retardant?

Yes, Phenolic Resin Laminate Sheets are inherently flame retardant and self-extinguishing, providing safety in various applications.

What quality control measures are in place?

Our production process includes rigorous quality control measures to ensure every sheet meets the highest standards of performance and reliability.