High Insulation Smc Fireproof Composite

Please click the button below to contact us.

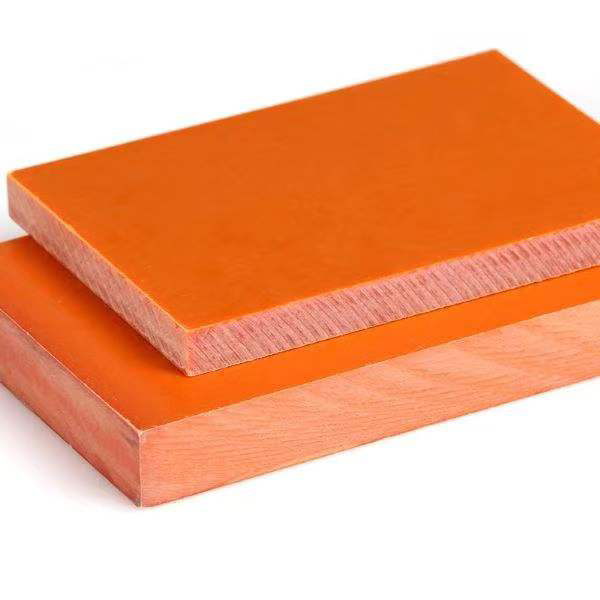

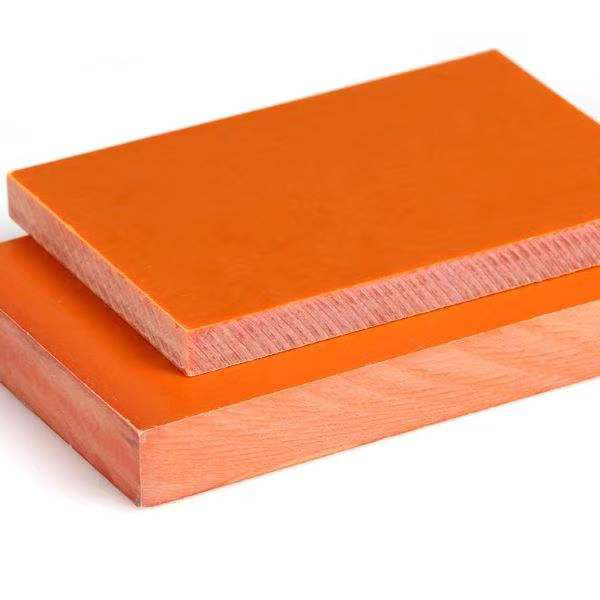

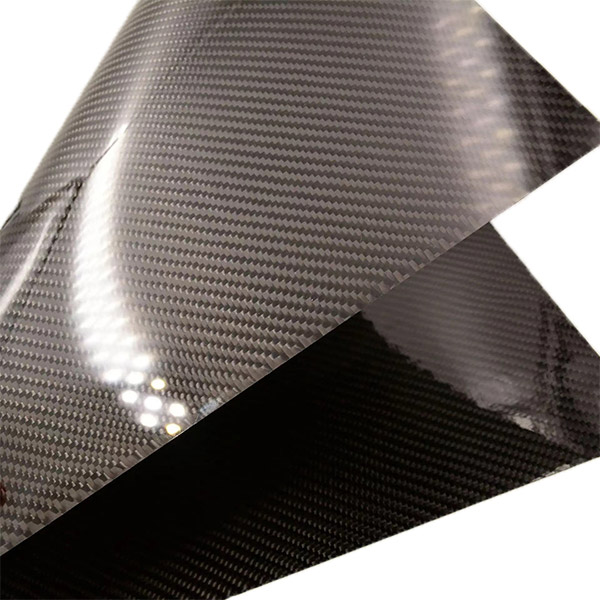

Introduction:SMC, or Sheet Molding Compound, is a composite material comprising long carbon or glass fibers dispersed in a resin bath of vinyl ester, polyester, or epoxy. This combination results in a robust final product known for its strength. Typically sold in rolls, SMC can be cut into smaller pieces called "charges" for various applications. Production involves integrating the fibers and resin by applying resin paste to a film, adding cut fibers, and compressing the mixture between two films. After storage to achieve the desired texture, compression molding applies heat and pressure to cure the SMC, yielding the finished product.

Product Description

SMC Sheet Molding Compound Parameters:

| Indicator name | unit | Index value | ||

| 4341 SMC-1 | 4343 SMC-2 | 4331 SMC-3 | ||

| Density | g/cm3 | 1.75~1.95 | ||

| water absorbency | mg | ≤20 | ||

| Molding Shrinkage | % | ≤0.15 | ≤0.30 | |

| Heat distortion temperature (method A) | ℃ | ≥240 | ≥220 | |

| Impact strength (simple bracket, no notch) | KJ/m2 | 290 | 260 | 245 |

| Bending strength | MPa | 2170 | ≥150 | ≥135 |

| Insulation resistance: normal | Q | ≥1.0×1013 | 1.0×1012 | |

| After soaking in water for 24 hours | ≥1.0×1012 | |||

| Electrical strength (in 90°C transformer oil) | MV/m | ≥12.0 | ≥10.0 | |

| Dielectric loss factor (1MHz) | S0.015 | |||

| Relative dielectric constant (1MHz) | ≤4.8 | |||

| Arc resistant | S | 2180 | ≥150 | |

| Tracking resistance index (PTl) | V | 2600 | ||

| Flammability | level | FVO | ||

| Long term heat resistance temperature index | 155 | 130 | ||

SMC Sheet Molding Compound Features:

- SMC Fireproof Composite Factory High Strength: SMC insulation boards have terrific mechanical houses such as tensile strength, bending strength, have an effect on strength, etc., which allow them to stand up to a variety of complicated working environments and exterior forces.

- High insulation performance: Due to the magnificent insulation houses of unsaturated polyester resin and glass fiber, SMC insulation board has excessive electrical resistivity and low dielectric constant, making it an best insulation cloth for electrical equipment.

- Corrosion resistance: SMC insulation board can withstand the corrosion of chemical elements such as acid, alkali, salt, etc., and keep steady overall performance for a lengthy time.

- Flame retardancy: SMC insulation board has properly flame retardancy, which can keep structural integrity at excessive temperatures and limit the danger of fire.

- Dimensional stability: SMC insulation board can shape a uniform shape in the course of the molding process, with low water absorption and warpage, making sure the dimensional balance of the product.

- Lightweight: SMC insulation board has the attribute of lightweight, lowering the weight of the product and enhancing the transportation and set up effectivity of the product.

- Easy to process: SMC insulation board has right formability and can be designed, processed, and molded in accordance to necessities to meet the desires of a number fields.

SMC Sheet Molding Compound Application:

- Power industry: SMC insulation board is extensively used in the energy industry, primarily for insulation and guide of high-voltage switchgear, transformers, transformers, bus ducts and different equipment.

- Automotive industry: In the car industry, SMC insulation board is used to manufacture aspects such as auto bodies, the front and rear bumpers, instrument panels, etc. Its lightweight, high-strength, and corrosion-resistant traits enhance the universal overall performance of cars.

- Construction industry: SMC insulation board is used as constructing substances such as roof photo voltaic panels and soundproof panels in the building industry. Its waterproof, anti-corrosion, and flame-retardant homes grant long-term safety for buildings.

- Shipbuilding industry: In the shipbuilding industry, SMC insulation board is used for cabin indoors decoration, engine compartment partitions, bridges, ship hulls and different parts. Its lightweight, anti-corrosion, stress resistant, and wear-resistant traits can meet the wishes of long-term maritime navigation.

- Machine manufacturing: SMC insulation board is more and more broadly used in the computer manufacturing industry, such as energy tools, agricultural machinery, panels, etc. Its traits of mild weight, corrosion resistance, and effortless processing assist manage manufacturing costs.

- Electrical Industry and Communication Engineering: The software of SMC merchandise in electrical enterprise and conversation engineering frequently consists of electrical enclosures, electrical elements and parts, such as electrical change boxes, SMC electrical wiring boxes, instrument panel covers, SMC insulators, insulation tools, motor quit caps, etc.

- Bathroom applications: Shower tools made of SMC composite substances can furnish visible and tactile enjoyment, and the fee can compete with ceramic tiles or enamel products, with many form changes.

- Ground material: The largest function of anti-static SMC floor is the use of anti-static SMC composite fabric fundamental molding technology. The product floor adopts anti slip design, which has the blessings of static conductivity, wear resistance, corrosion resistance, getting older resistance, hearth resistance, compression resistance, etc.

- Explosion proof electrical tools casing: The software of SMC composite fabric in explosion-proof electrical gear casing merchandise has modified the preceding scenario the place metal and aluminum have been the principal substances used in explosion-proof electrical tools casing products. The software of SMC cloth overcomes the negative aspects of cumbersome metal and aluminum casings of explosion-proof electrical equipment, which can without difficulty produce sparks when collided.

SMC Sheet Molding Compound FAQs:

What is SMC?

SMC, or Sheet Molding Compound, is a composite material typically used in manufacturing processes. It consists of a thermosetting resin, reinforcing fibers, and various additives.

What are the advantages of using SMC over other materials?

SMC offers numerous advantages including high strength-to-weight ratio, corrosion resistance, dimensional stability, and excellent surface finish. It is also highly moldable and suitable for complex shapes.

What industries commonly use SMC products?

SMC products find applications in diverse industries such as automotive, electrical, construction, aerospace, and telecommunications due to their versatility and performance characteristics.

Can SMC be customized for specific applications?

Yes, SMC can be tailored to meet specific application requirements by adjusting the resin formulation, fiber content, and additives, ensuring optimal performance and functionality.

Are your SMC products environmentally friendly?

Yes, our SMC products are environmentally friendly as they are recyclable and emit low volatile organic compounds (VOCs) during manufacturing, contributing to sustainability efforts.

Do you offer customization options for color and finish?

Yes, we offer customization options for color and finish to meet the aesthetic and branding requirements of our customers, providing flexibility in design and product differentiation.

What are the temperature and chemical resistance properties of your SMC products?

Our SMC products exhibit excellent temperature and chemical resistance properties, making them suitable for demanding environments and applications where exposure to extreme conditions is common.

What is your approach to quality control and assurance during manufacturing?

Our manufacturing process incorporates rigorous quality control and assurance measures at every stage, including raw material inspection, production monitoring, and final product testing, to ensure adherence to quality standards and customer satisfaction.