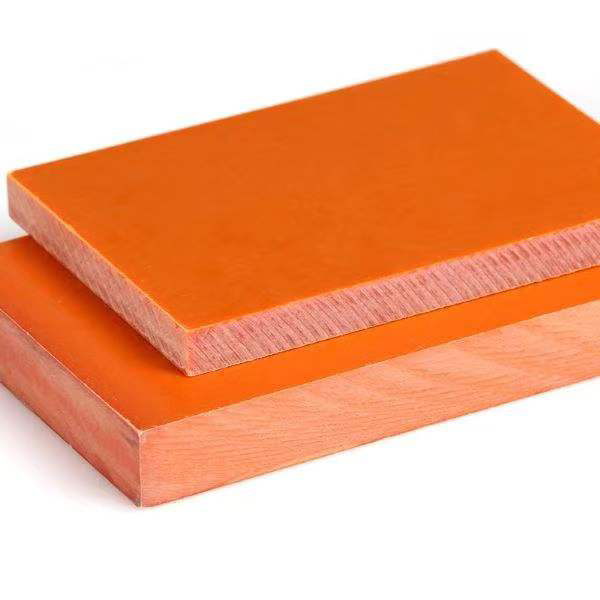

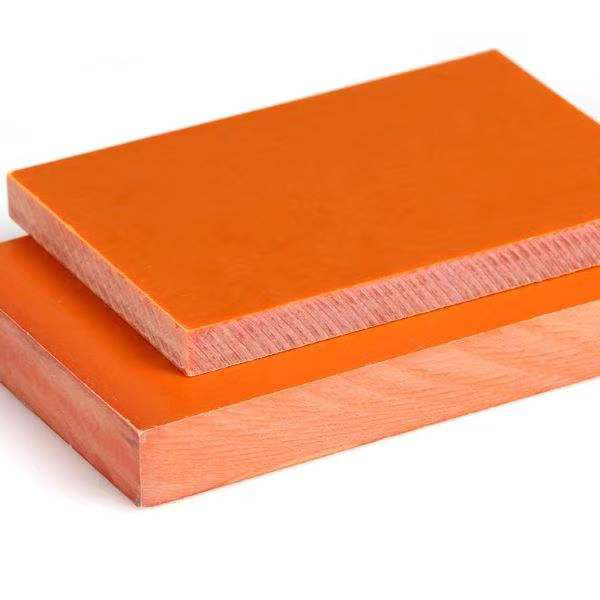

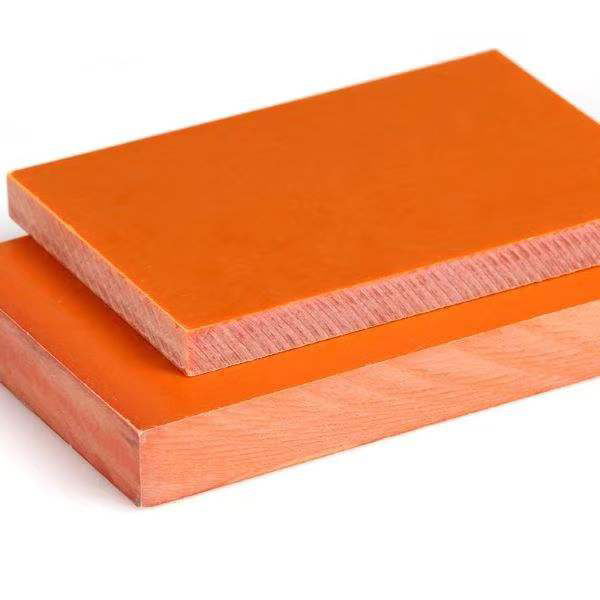

High Strength Resin Insulation Fireproof Composite

Please click the button below to contact us.

Introduction:Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4 is one of the composite materials that are widely used in electronics. Its components consist of glass fiber cloth soaked in resin called epoxy, and after this it gets hardened through heat or pressure to become a stiff and resilient sheet.

Product Description

Fireproof composite substances are designed to furnish gold standard fireplace safety in a range of applications. These substances are engineered to stand up to intense temperatures and stop the unfold of flames in the match of a fire.

Parameters:

| Indicator Name | Unit | Indicator Value | |

| Density | g/cm³ | 1.8–2.0 | |

| Water absorption | % | ≤ 0.5 | |

| Vertical layer bending strength | MPa | ≥ 340 | |

| Vertical layer compression strength | MPa | ≥ 350 | |

| Parallel layer impact strength (simple beam method notch) | K J/m² | ≥ 37 | |

| Parallel layer shear strength | MPa | ≥ 34 | |

| Tensile strength | MPa | ≥ 300 | |

| Vertical layer direction electric strength (90 ℃± 2 ℃ in oil) | 1mm | KV/mm | ≥ 14.2 |

| 2mm | ≥ 11.8 | ||

| 3mm | ≥ 10.2 | ||

| Parallel layer direction breakdown voltage (90 ℃± 2 ℃ in oil) | KV | ≥ 40 | |

| Dielectric loss factor (50 Hz) | – | ≤ 0.04 | |

| Insulation resistance | Normality | Ω | ≥ 5.0 × 1012 |

| After immersed in water for 24h | ≥ 5.0 × 1010 | ||

| Flammability (UL-94) | Rating | V-0 | |

Features:

- Excellent fireplace resistance: Customized fire-resistant composite substances can face up to excessive temperatures and face up to ignition in the tournament of a fire, supplying a safer outside environment.

- High security standards: Meet strict protection requirements and policies set up by way of constructing codes and fireplace departments, and furnish gold standard furnace hazard protection.

- Durability and lengthy lifespan: in a position to stand up to more than a few factors together with moisture, ultraviolet radiation, and temperature fluctuations, keeping its structural integrity and aesthetics.

- Moisture resistance and decay resistance: prevents moisture infiltration, reduces the danger of mold, mildew, and decay, appropriate for outside environments.

- Green and environmentally friendly: Made from recycled materials, decreasing the demand for uncooked substances and minimizing waste to the best extent possible.

- Aesthetic Design: Provides a range of colors, textures, and finishes to select from, permitting for customization of out of doors areas based totally on non-public fashion preferences and plan aesthetics.

- Low renovation requirements: minimal protection is needed, and normal cleansing with cleaning soap and water is enough to preserve top-quality condition.

- Thermal insulation and cooling: It has gorgeous thermal insulation and cooling performance, for example, some merchandise can gain a thermal insulation and cooling gradient of 627 ℃ (1mm).

- High bonding strength: It has a excessive bonding strength, such as 30MPa, to make certain the steadiness and sturdiness of the material.

- Heat resistance duration: capable to face up to excessive excessive temperatures, such as a thousand ℃ for 1 hour.

- High quantity of thermal cycles: Has correct thermal cycle tolerance, such as 1352 thermal cycles.

Application:

- Building exterior wall: used for exterior wall insulation and ornament of buildings, supplying furnace prevention, insulation, and ornamental functions.

- Interior Decoration: Used for indoors decoration, such as partitions and ceilings, to supply aesthetics whilst making sure furnace safety.

- Rail transit: used for indoors and exterior ornament of rail transit cars to beautify hearth safety.

- Medical facilities: Used for indoors ornament of scientific facilities, presenting a fire-resistant and environmentally pleasant indoor environment.

- Commercial and Public Spaces: Used for business pedestrian streets, resorts, and different public spaces, supplying secure and long lasting out of doors ground solutions.

- Residential applications: Used for domestic courtyards and out of doors entertainment areas, presenting a lovely and secure out of doors residing environment.

- Industrial applications: Used in industrial environments that require hearth protection, such as chemical and manufacturing facilities.

FAQ:

What is Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4 is a type of composite material composed of woven fiberglass cloth impregnated with an epoxy resin binder. It is known for its excellent electrical insulation properties and mechanical strength.

What are the key features of Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4 offers high mechanical strength, good electrical insulation properties, flame resistance, and excellent dimensional stability.

What industries commonly use Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s find extensive use in industries such as electronics, telecommunications, automotive, aerospace, and electrical equipment manufacturing due to their superior insulation and mechanical properties.

Can Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s be customized according to specific requirements?

Yes, we offer customization services for Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s to meet the specific size, thickness, and surface finish requirements of our customers.

Are Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s compliant with industry standards and regulations?

Yes, our Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s adhere to industry standards and regulations such as [specify relevant standards or certifications], ensuring quality and reliability.

What are the advantages of using Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s over other materials?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s offer advantages such as high strength-to-weight ratio, excellent electrical insulation, flame resistance, and dimensional stability, making them ideal for various demanding applications.

Can Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s be machined or fabricated easily?

Yes, Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s can be easily machined, drilled, milled, and fabricated using standard woodworking tools or CNC machinery, allowing for precise customization.

Do Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s require any special handling or storage conditions?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s should be stored in a dry and cool environment away from direct sunlight and moisture to maintain their properties. Proper handling techniques should be followed to prevent damage.

What is the recommended method for bonding or joining Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s can be bonded using epoxy adhesives specifically formulated for bonding fiberglass materials. Surface preparation and proper adhesive selection are crucial for achieving strong and durable bonds.