Lightweight And High-Strength Fiberglass Fireproof Composite

Please click the button below to contact us.

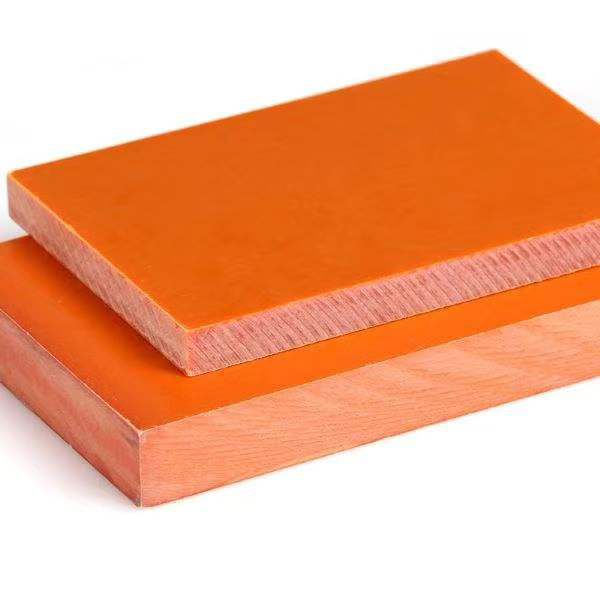

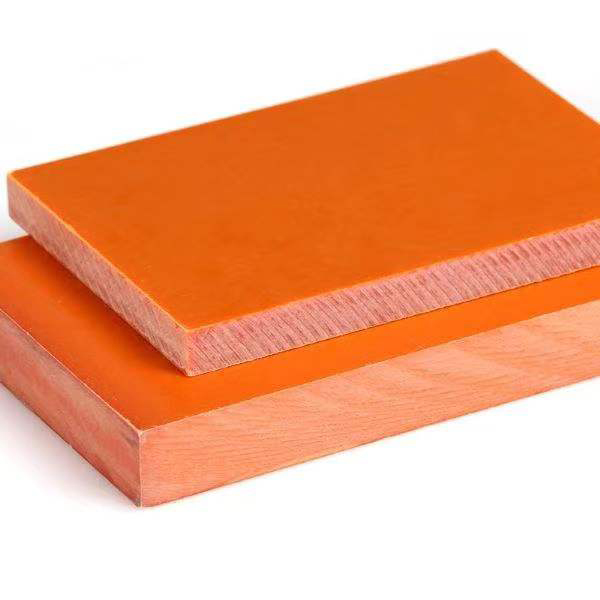

Introduction:GPO-3, a glass reinforced thermoset polyester sheet material, boasts strength, stiffness, and dimensional stability, making it ideal for electrical insulating applications. Additionally, its excellent electrical properties, including flame, arc, and track resistance, ensure reliable performance in demanding environments.

Product Description

Fiberglass fireproof composite substances are a modern innovation in the subject of fireplace protection. Composed of high-strength fiberglass cloth and a specialised fire-resistant resin, these composites provide most reliable fireproofing houses that outperform regular constructing materials.

GPO-3 Fiberglass Sheet Parameters:

| Physical Properties | Parameters |

| Specific gravity (ASTM D-792) | 1.81 |

| Tensile strength (ASTM D-638)Ps | 8000 |

| Compressive strength (ASTM D-695) Psi | 33100 |

| Flexural strength (ASTM D-790)Ps | 22100 |

| ZOD impact strength (notched) (ASTM D-256) ft.Ib/in | 8.9 |

| Water absorption (ASTM D-570)% | 0.4 |

| Electrical Properties | |

| Electrical strength (ASTM D-149)Vpm | 450 |

| Arc resistance (ASTM D-495) seconds. | 180 |

| Thermal Properties | |

| UL Topic 94 (0.094 inches and thicker) | V0 |

| UL temperature temperature index (UL746B) | |

| Electric | 130°℃ (266°F) |

| Mechanical | 160°℃ (320°F) |

| Thermal expansion coefficient (ASTM D-696)in/in/°CX10-5 | 2 |

| Thermal Conductivity (ASTM C-177) BTU/HR/Ft²/In/°F | 1.9 |

GPO-3 Fiberglass Sheet Features:

- Lightweight and High Strength: Fiberglass composite substances are recognized for their light-weight and excessive strength, offering fantastic power to weight ratios.

- Corrosion resistance: It has robust corrosion resistance, making it function properly in harsh or corrosive environments, such as the marine and chemical processing industries.

- Heat resistance: Glass fiber composite substances have exact warmth resistance and can hold overall performance in excessive temperature environments.

- Electrical insulation: Due to the electrical insulation houses of glass fiber, composite substances additionally have most advantageous electrical insulation performance.

- Flame retardant performance: Glass fiber composite substances generally have flame retardant residences and are appropriate for functions that require fireplace prevention.

- Design flexibility: Fiberglass composite substances can be molded into any form and size, appropriate for a range of product designs.

- Durability: Known for its sturdiness and put on resistance, appropriate for heavy-duty applications.

GPO-3 Fiberglass Sheet Application:

- Aerospace: Components used for plane fuselage, cabin indoors parts, and insulation panels, with light-weight traits that assist enhance gasoline effectivity and ordinary performance.

- Marine engineering: used for ship hulls, decks, and masts due to their capacity to withstand water and salt corrosion, as properly as face up to the stresses of the marine environment.

- Automotive industry: used for manufacturing automobile elements such as bumpers, physique panels, and instrument panels to enhance car overall performance and efficiency.

- Construction industry: an perfect preference for reinforcing substances used in roofs, pipes, and concrete, as nicely as thermal and acoustic applications.

- Sports equipment: used for manufacturing skis, hockey sticks, bicycle and racing parts, etc., as it can be molded into complicated shapes and is light-weight and strong.

- Wind strength and photovoltaics: used for manufacturing fiberglass blades and unit covers due to their light-weight and superior effects.

- Chemical chemistry: used for manufacturing chemical containers (such as storage tanks), anti-corrosion grilles, etc., due to its desirable corrosion resistance and most excellent reinforcement effect.

- Infrastructure: Used for bridges, docks, motorway pavements, overpasses, waterfront buildings, pipelines, etc., due to its true dimensional balance and best reinforcement performance.

- Electronic and electrical: used for electrical enclosures, electrical elements and parts, transmission lines, etc., due to its electrical insulation and corrosion resistance.

GPO-3 Fiberglass Sheet FAQs:

What is GPO-3 Fiberglass Sheet made of?

GPO-3 Fiberglass Sheet is composed of fiberglass reinforcement materials combined with polyester resins.

What are the primary applications of GPO-3 Fiberglass Sheet?

GPO-3 Fiberglass Sheet is commonly used in electrical insulation applications such as switchgear, bus bar supports, and electrical enclosures due to its excellent electrical insulation properties and flame resistance.

How does GPO-3 Fiberglass Sheet compare to other insulation materials?

GPO-3 Fiberglass Sheet offers superior electrical insulation properties, high mechanical strength, and excellent flame resistance compared to many other insulation materials.

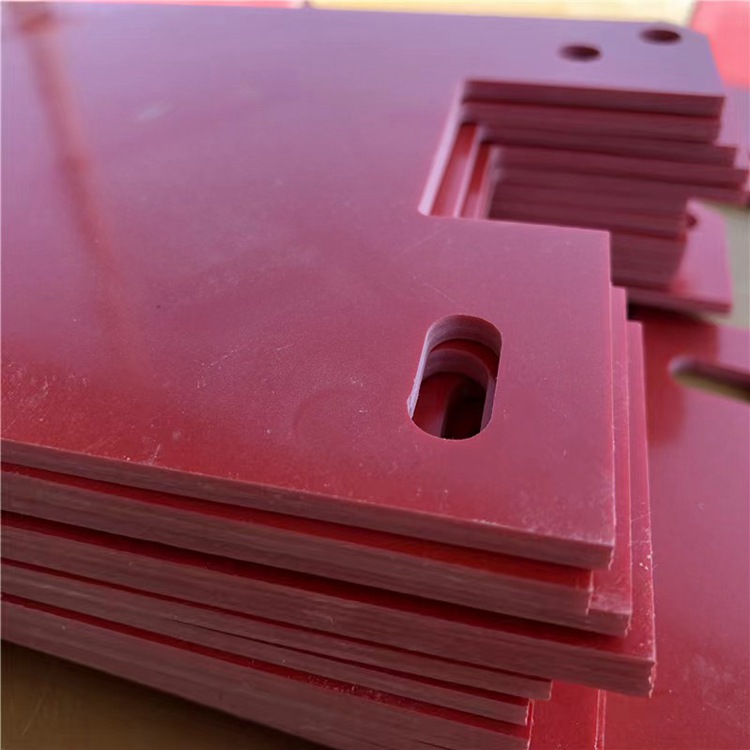

Can GPO-3 Fiberglass Sheet be machined or fabricated?

Yes, GPO-3 Fiberglass Sheet can be easily machined, drilled, sawed, and fabricated using standard tools and techniques.

What thicknesses are available for GPO-3 Fiberglass Sheet?

GPO-3 Fiberglass Sheet is available in various thicknesses ranging from 0.5mm to 50mm to suit different application requirements.

Does GPO-3 Fiberglass Sheet require special handling or storage?

GPO-3 Fiberglass Sheet should be stored in a dry environment away from direct sunlight and moisture to maintain its electrical and mechanical properties.

Can GPO-3 Fiberglass Sheet be customized in terms of color or surface finish?

Yes, GPO-3 Fiberglass Sheet can be customized in terms of color and surface finish to meet specific customer requirements.

What testing and quality control measures are in place for GPO-3 Fiberglass Sheet?

GPO-3 Fiberglass Sheet undergoes rigorous testing and quality control procedures to ensure compliance with industry standards and specifications.