Manufacturer'S Factory Price for Fireproof Composite

Please click the button below to contact us.

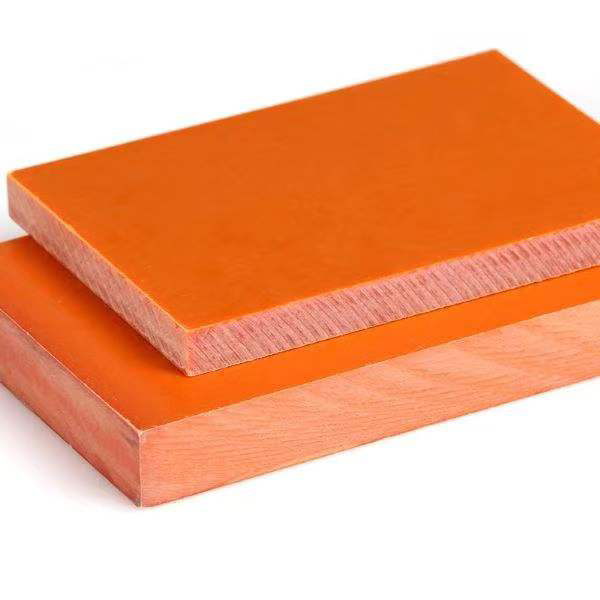

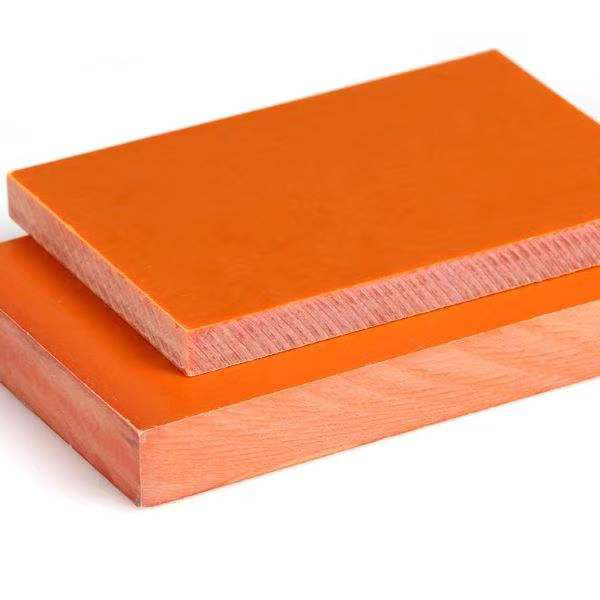

Introduction:Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4 is one of the composite materials that are widely used in electronics. Its components consist of glass fiber cloth soaked in resin called epoxy, and after this it gets hardened through heat or pressure to become a stiff and resilient sheet.

Product Description

Parameters:

| Indicator Name | Unit | Indicator Value | |

| Density | g/cm³ | 1.8–2.0 | |

| Water absorption | % | ≤ 0.5 | |

| Vertical layer bending strength | MPa | ≥ 340 | |

| Vertical layer compression strength | MPa | ≥ 350 | |

| Parallel layer impact strength (simple beam method notch) | K J/m² | ≥ 37 | |

| Parallel layer shear strength | MPa | ≥ 34 | |

| Tensile strength | MPa | ≥ 300 | |

| Vertical layer direction electric strength (90 ℃± 2 ℃ in oil) | 1mm | KV/mm | ≥ 14.2 |

| 2mm | ≥ 11.8 | ||

| 3mm | ≥ 10.2 | ||

| Parallel layer direction breakdown voltage (90 ℃± 2 ℃ in oil) | KV | ≥ 40 | |

| Dielectric loss factor (50 Hz) | – | ≤ 0.04 | |

| Insulation resistance | Normality | Ω | ≥ 5.0 × 1012 |

| After immersed in water for 24h | ≥ 5.0 × 1010 | ||

| Flammability (UL-94) | Rating | V-0 | |

Features:

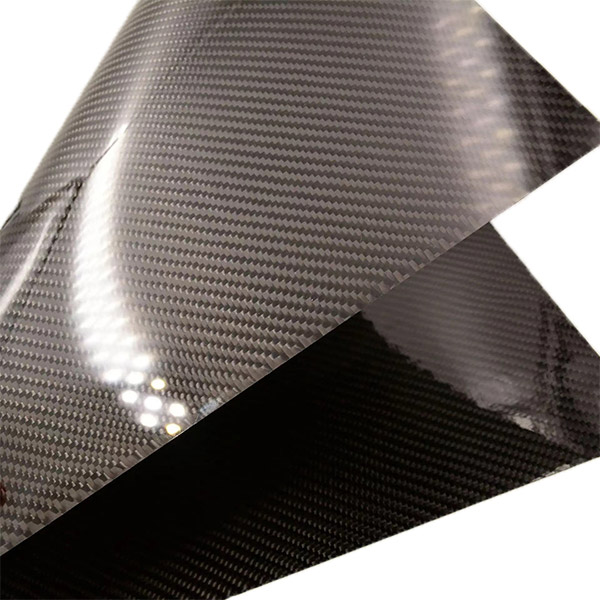

- Lightweight and High Strength: Fireproof Composite is typically composed of reinforced carbon fiber or glass fiber in an organic resin matrix, providing a lightweight and high-strength structure.

- Fireproof performance: Fireproof Composite can meet specific fire protection requirements, such as fire standards for wall, ceiling, and floor covering materials.

- Low heat release rate: The low heat release rate of Fireproof Composite means that less heat is released during combustion, reducing the risk of fire.

- Thermal insulation: Fireproof Composite such as SiO2 gas gel has high specific surface area, high porosity and low thermal conductivity, which makes it perform well in thermal insulation.

- Environmental stability: Fireproof Composite has good stability under high temperature conditions, is not easily decomposed, and is suitable for applications that require fire protection.

- Multifunctionality: Fireproof Composite not only provides fire protection, but may also have other functions such as sound absorption, increasing the diversity of its applications.

- Environmental friendliness: With increasing attention to environmental impact, the development of Fireproof Composite places greater emphasis on using eco-friendly materials to reduce the release of toxic gases and chemicals.

Application:

- Aerospace field: Fireproof Composite is used in the aerospace industry to produce lightweight structures while maintaining stability under extreme high temperatures, reducing the risk of decomposition and collapse in the event of a fire.

- Railway and maritime industry: In the railway and maritime industry, Fireproof Composite is used to improve the structural fire resistance of vehicles and ships, ensuring passenger safety.

- Construction industry: Fireproof Composite is used for building insulation layers. Compared with traditional insulation materials, it has lower heat loss and stronger durability, making it suitable for civil building insulation.

- Passive fire protection system: In passive fire protection systems such as urban underground spaces, super insulating fireproof materials play an important role due to their ultra-low thermal conductivity and nano porous structure.

FAQ:

What is Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4 is a type of composite material composed of woven fiberglass cloth impregnated with an epoxy resin binder. It is known for its excellent electrical insulation properties and mechanical strength.

What are the key features of Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4 offers high mechanical strength, good electrical insulation properties, flame resistance, and excellent dimensional stability.

What industries commonly use Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s find extensive use in industries such as electronics, telecommunications, automotive, aerospace, and electrical equipment manufacturing due to their superior insulation and mechanical properties.

Can Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s be customized according to specific requirements?

Yes, we offer customization services for Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s to meet the specific size, thickness, and surface finish requirements of our customers.

Are Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s compliant with industry standards and regulations?

Yes, our Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s adhere to industry standards and regulations such as [specify relevant standards or certifications], ensuring quality and reliability.

What are the advantages of using Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s over other materials?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s offer advantages such as high strength-to-weight ratio, excellent electrical insulation, flame resistance, and dimensional stability, making them ideal for various demanding applications.

Can Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s be machined or fabricated easily?

Yes, Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s can be easily machined, drilled, milled, and fabricated using standard woodworking tools or CNC machinery, allowing for precise customization.

Do Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s require any special handling or storage conditions?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s should be stored in a dry and cool environment away from direct sunlight and moisture to maintain their properties. Proper handling techniques should be followed to prevent damage.

What is the recommended method for bonding or joining Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s?

Electrical Insulation Epoxy Resin Fiberglass Sheet Fr4s can be bonded using epoxy adhesives specifically formulated for bonding fiberglass materials. Surface preparation and proper adhesive selection are crucial for achieving strong and durable bonds.