Industrial Application Non Flame Retardant Composite

Please click the button below to contact us.

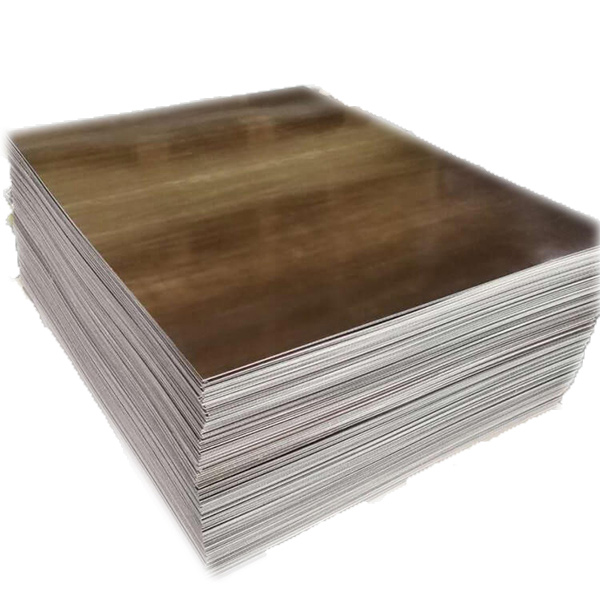

Introduction:This G9 Glass Melamine Laminate for Versatile Applications is made of alkali-free glass cloth impregnated with melamine formaldehyde resin by drying and hot pressing. It has good arc resistance and certain dielectric properties and flame retardant properties.

Product Description

Parameters:

| Indicator name | Unit | Indicator Value | |

| Density | g/cm³ | 1.8–2.0 | |

| Water absorption | % | ≤ 3.0 | |

| Vertical layer bending strength | MPa | ≥ 200 | |

| Parallel layer impact strength (simple beam method notch) | K J/m² | ≥ 25 | |

| Vertical layer direction electric strength (90 ℃± 2 ℃ in oil) | 1mm | KV/mm | ≥ 7.0 |

| 2mm | ≥ 5.4 | ||

| 3mm | ≥ 5.0 | ||

| Parallel layer direction breakdown voltage (90 ℃± 2 ℃ in oil) | KV | ≥ 15 | |

| Insulation resistance | Normality | Ω | ≥ 1.0 × 1012 |

| After immersed in water for 24h | ≥ 1.0 × 108 | ||

| Flammability (UL-94) | Level | – | |

Features:

- High strength and rigidity: Due to the presence of glass fiber reinforced materials, G9 glass melamine laminated composite materials have high strength and rigidity, and can withstand large mechanical stresses.

- Wear resistant and scratch resistant: The surface has been specially treated to have excellent wear resistance and scratch resistance, suitable for high flow areas and frequent use scenarios.

- Chemical corrosion resistance: It has good resistance to many common chemicals such as acids, bases, and solvents, and is suitable for environments that require corrosion resistance.

- Good dimensional stability: It can maintain stable dimensions and is not easily deformed even under temperature and humidity changes.

- Easy to process and install: It can be processed through various methods such as cutting, drilling, and polishing, making it easy to install and maintain.

- Beautiful and diverse: The surface can be treated with various colors and textures, providing rich design choices to meet different aesthetic needs.

- Cost effectiveness: Compared to other high-performance materials, G9 glass melamine laminated composite materials have lower costs and higher cost-effectiveness.

- Non flame retardant properties: It should be noted that this material is non flame retardant, so additional fire-resistant treatment or selection of other flame retardant materials may be necessary in situations where fire resistance is required.

Applications:

- Architecture and Interior Decoration: Walls and Ceilings: Decorative panels used for indoor and outdoor walls and ceilings, providing a beautiful and durable surface.

- Partition and Screen: Used as partition and screen materials in offices, hotels, or commercial spaces.

- Furniture manufacturing: desktop and countertop: used for making office desks, dining tables, kitchen countertops, etc., with the characteristics of wear resistance and scratch resistance.

- Cabinets and wardrobes: As cabinet door panels and wardrobe linings, they provide a sturdy and easy to clean surface.

- Industrial applications: Control panels and instrument enclosures: used to manufacture enclosures for industrial control panels, instruments, and equipment, providing good mechanical properties and chemical stability.

- Electrical equipment: used for the internal structure and external covering of electrical equipment such as cabinets and distribution boxes.

- Transportation: Vehicle Interior: Used for interior decoration of vehicles such as cars, trains, airplanes, etc., such as seat backrests, side panels, etc.

- Ship interior: Used for interior decoration of yachts and commercial vessels, providing waterproof and corrosion-resistant surfaces.

- Outdoor facilities: Billboards and signage: used for outdoor billboard and signage systems, with good weather resistance and UV resistance.

- Public facilities: Surface materials for public facilities such as park benches and bus stops.

FAQ:

What is G9 Glass Melamine Laminate?

G9 Glass Melamine Laminate is a premium surfacing material renowned for its durability, versatility, and aesthetic appeal. It's crafted by fusing multiple layers of resin-impregnated decorative paper onto layers of kraft paper core, under high heat and pressure, resulting in a robust and visually stunning laminate.

What are the key features of G9 Glass Melamine Laminate?

G9 Glass Melamine Laminate offers exceptional scratch resistance, impact strength, and heat resistance. It is also resistant to stains, chemicals, and moisture, making it ideal for various applications in both residential and commercial settings.

How does G9 Glass Melamine Laminate compare to other surfacing materials?

G9 Glass Melamine Laminate stands out for its unparalleled durability and design versatility. Unlike some traditional materials, it maintains its integrity even in high-traffic areas and challenging environments, while offering an extensive range of colors, patterns, and textures to suit diverse design preferences.

What applications is G9 Glass Melamine Laminate suitable for?

G9 Glass Melamine Laminate is suitable for a wide range of applications, including but not limited to countertops, cabinetry, furniture, wall panels, and partitions in residential, commercial, and institutional settings.

Can G9 Glass Melamine Laminate be customized to specific design requirements?

Yes, G9 Glass Melamine Laminate can be customized to meet specific design requirements, including color matching, texture selection, and sizing options, providing flexibility and creative freedom for tailored solutions.

What maintenance is required for G9 Glass Melamine Laminate?

G9 Glass Melamine Laminate requires minimal maintenance. Regular cleaning with mild detergent and water is usually sufficient to keep it looking pristine. Avoid harsh chemicals and abrasive cleaners to preserve its finish and longevity.

How does G9 Glass Melamine Laminate perform in terms of fire safety?

G9 Glass Melamine Laminate meets stringent fire safety standards, offering excellent fire resistance properties. It is engineered to retard the spread of flames and minimize smoke emissions, enhancing overall safety in various applications.