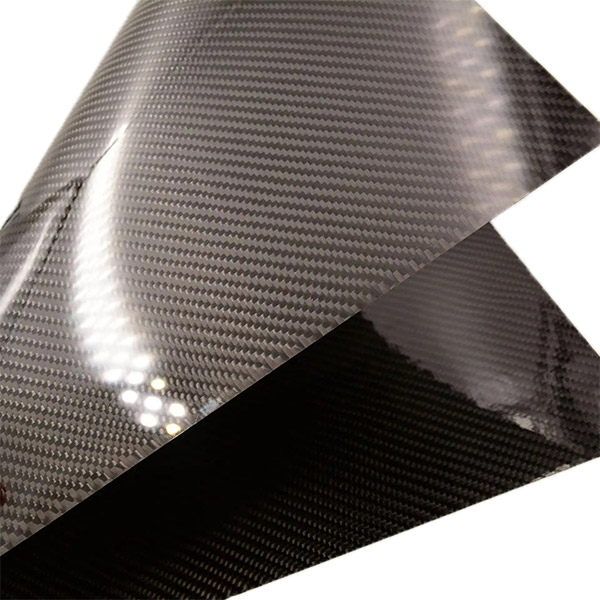

A Custom Carbon Fiber Laminated Panels is a lightweight and durable material crafted from carbon fibers that are tightly woven together and bonded with a resin. Carbon fiber materials are so strong that even materials made by lower grade carbon fibers.

This Fireproof Waterproof Resin Laminate Sheet FR2 is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. It has high mechanical properties, dielectric properties and flame retardant properties, good heat resistance and moisture resistance, and good machinability.

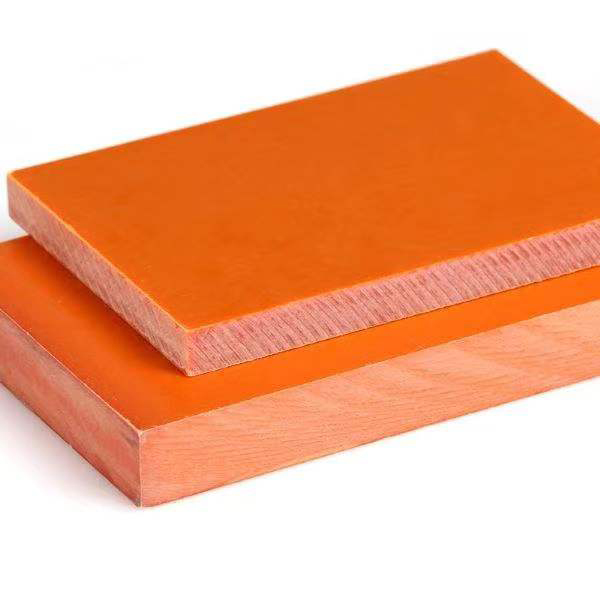

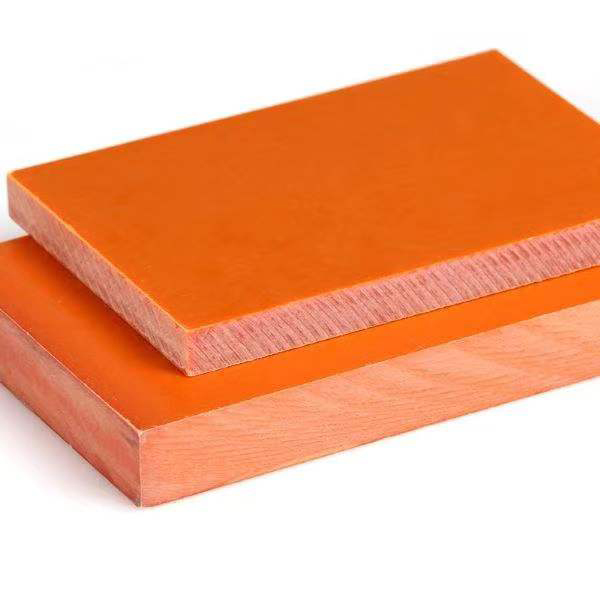

With its excellent thermal and electrical characteristics, Phenolic Cotton Cloth Sheet Fr1 is a special material that is commonly used in various industries. It comprises of flame retardant materials which guarantee safety in cases where there might be fire breakouts.

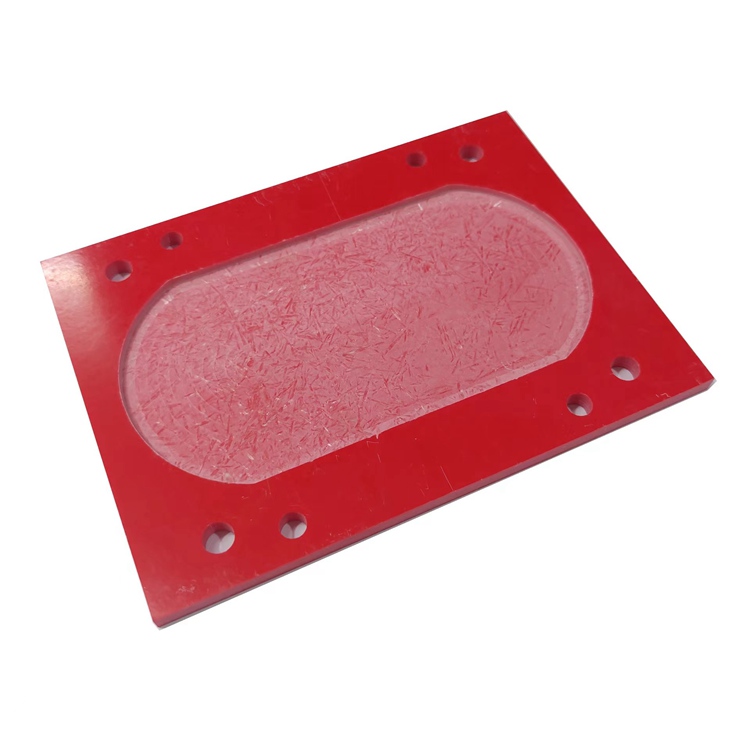

SMC insulating machined parts are meticulously crafted components designed for electrical insulation applications. Utilizing Sheet Molding Compound (SMC) material, these parts offer exceptional dielectric strength, thermal stability, and mechanical resilience.

SMC insulating machined parts are meticulously crafted components designed for electrical insulation applications. Utilizing Sheet Molding Compound (SMC) material, these parts offer exceptional dielectric strength, thermal stability, and mechanical resilience.

With its excellent thermal and electrical characteristics, FR1 material sheet is a special material that is commonly used in various industries. It comprises of flame retardant materials which guarantee safety in cases where there might be fire breakouts.

This Phenolic Resin Laminate Sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. It has high mechanical properties, dielectric properties and flame retardant properties, good heat resistance and moisture resistance, and good machinability. Composite materials are widely used in electronics and FR-4 Glass Epoxy Sheet is a typical example of that. It is made up of a woven fiberglass cloth, which has been soaked with epoxy resin and then hardened at high temperature and pressure to form a tough rigid sheet. These sheets have excellent electrical insulation properties, high mechanical strength and are capable of resisting heat damage as well as reaction with many chemicals. They are the most commonly used substrate materials for printed circuit boards (PCBs) because they can support complex circuitry configurations while surviving hostile operating environments . FR-4 sheets are also fire-retardant hence this attribute makes them an ideal choice for applications demanding fire safety precautions.

FR4 fiberglass sheet is one of the composite materials that are widely used in electronics. Its components consist of glass fiber cloth soaked in resin called epoxy, and after this it gets hardened through heat or pressure to become a stiff and resilient sheet.

GPO-3, a glass reinforced thermoset polyester sheet material, boasts strength, stiffness, and dimensional stability, making it ideal for electrical insulating applications. Additionally, its excellent electrical properties, including flame, arc, and track resistance, ensure reliable performance in demanding environments.

SMC, or Sheet Molding Compound, is a composite material comprising long carbon or glass fibers dispersed in a resin bath of vinyl ester, polyester, or epoxy. This combination results in a robust final product known for its strength. Typically sold in rolls, SMC can be cut into smaller pieces called "charges" for various applications. Production involves integrating the fibers and resin by applying resin paste to a film, adding cut fibers, and compressing the mixture between two films. After storage to achieve the desired texture, compression molding applies heat and pressure to cure the SMC, yielding the finished product.